These industrial shredders come in a variety of sizes and can have applications in many industries where large waste needs to be condensed before disposal. Some of the most common types of shredders use shaft grinders, hammer mills, slow speed sheers or refining mills to process materials. Sometimes waste shredding is just the beginning of the recycling process, particularly for recycled metals. Read More…

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

Tackling the toughest shredding problems since 1980, SSI Shredding Systems designs, manufactures and supports today's most versatile shredders and size reduction solutions.

Our long established Saturn-brand industrial shredders are designed with cost and innovation in mind, and provide the benefit you need no matter what you need to shred!

At Amos Mfg., Inc., we specialize in designing and manufacturing high-quality industrial shredders that are built to handle the toughest materials. With years of experience in the industry, we take pride in offering durable, efficient, and reliable shredding solutions tailored to meet the unique needs of our clients.

More Waste Shredder Manufacturers

Waste shredders can be built to run on electrical or gas power and many of the larger ones run on a gas powered generator that puts out enough horsepower to process objects as large as old cars and appliances. Most shredders process materials by running them through a series of rotating discs and blades that crush them and then forcefully separate them so that the remaining materials can be easily condensed for disposal or repurposing.

Some waste shredding units have a conveyor belt attached to them. This belt carries that shredded waste to a bin or depository, preventing the waste from quickly building up around the machine if it is used frequently.

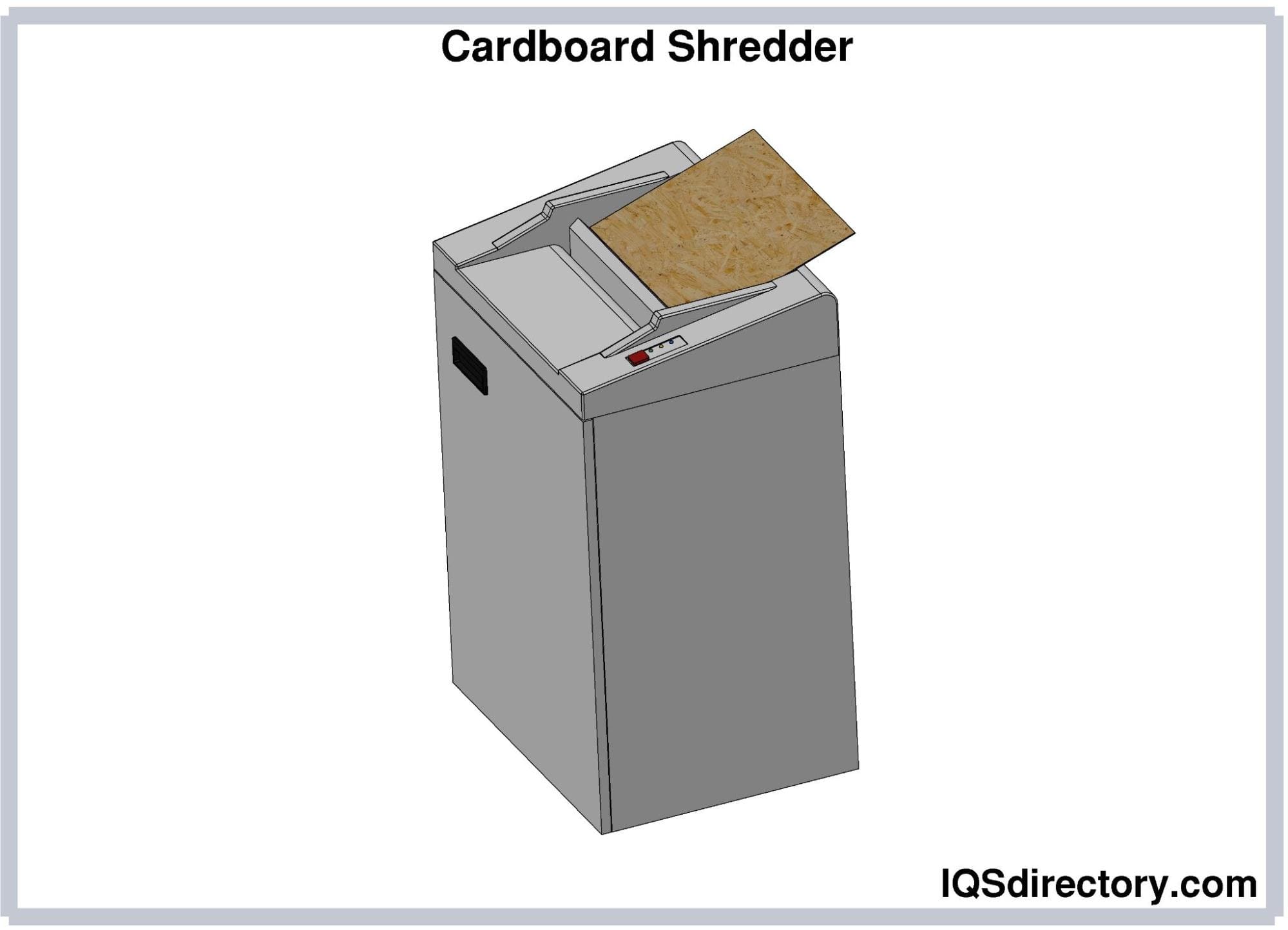

Most waste shredders have a hopper located on the top of the machine. This hopper is where the waste must be placed. From here it is pulled directly into the machine to be shredded. This equipment can be very dangerous, so it is important that the appropriate safety precautions are used when operating a waste shredder. A control and management system is attached to the shredder, and this can be used to operate the machine by controlling speeds and output.

Waste shredders are equipped with an emergency stop feature that immediately shuts the entire system down if someone is in danger or if material somehow becomes jammed in the mechanism. Most waste shredder manufacturers offer support for their systems, so you can contact them for repairs if you experience any mechanical issues.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services