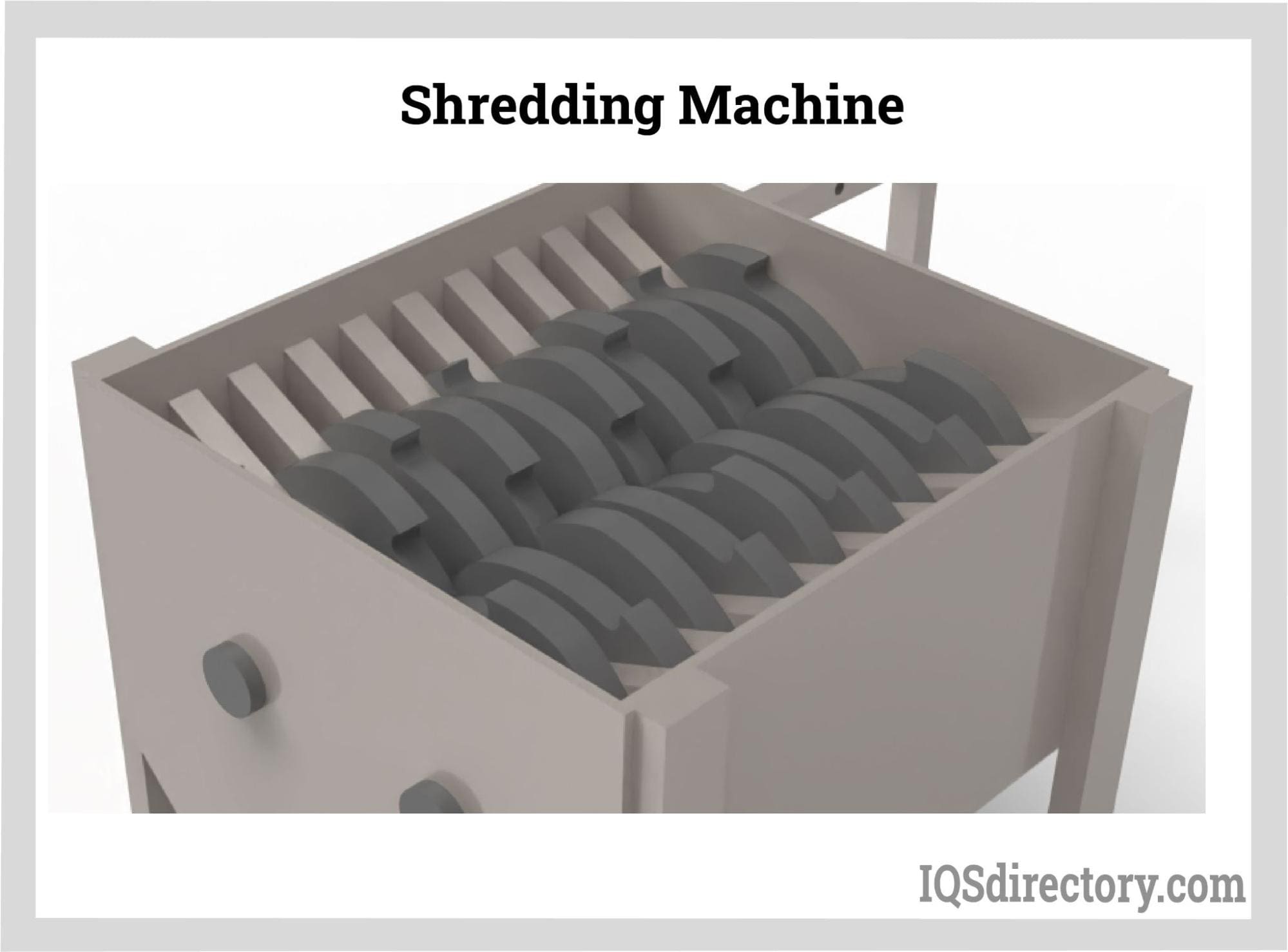

The device used for shredding is called a shredding machine. Materials are reduced in size using shredding machines. Even though most shredding machines are considered as equipment used to shred documents for privacy protection, shredding machines can take on many different forms depending on the type of material being destroyed. Industrial waste shredders are essential for managing garbage and recycling in today’s manufacturing and disposal sectors. Read More…

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

Tackling the toughest shredding problems since 1980, SSI Shredding Systems designs, manufactures and supports today's most versatile shredders and size reduction solutions.

Our long established Saturn-brand industrial shredders are designed with cost and innovation in mind, and provide the benefit you need no matter what you need to shred!

At Amos Mfg., Inc., we specialize in designing and manufacturing high-quality industrial shredders that are built to handle the toughest materials. With years of experience in the industry, we take pride in offering durable, efficient, and reliable shredding solutions tailored to meet the unique needs of our clients.

More Shredding Machine Manufacturers

However, after carefully weighing the importance of reducing environmental effects, security, waste management costs, and other factors, they are also useful for other organizations or business communities. Therefore, it's crucial to understand which shredder is the most cost-effective and appropriate for a particular application. Mega-shredders are advantageous in large-scale garbage disposals systems, such as municipal landfills and recycling facilities.

It is possible to instantly reduce materials like plastics, wood, rubber, asphalt, and others to a tiny fraction of their original size. These materials can then be sold or donated to the general public to be distributed as useful items. In addition, after being shredded, biodegradable goods will break down more quickly. Shredding also makes it possible to compact waste materials that will be buried in landfills for all time into a smaller area with fewer voids, creating a more secure foundation for future construction.

Three Methods of Shredding

Material Shearing in Shredding Equipment

Shearing involves actual material cutting. Similar to how scissors work, the effectiveness of shearing depends on how sharp the opposing cutting edges are and how much room there is between them. Clean cuts are guaranteed even after a lengthy working period because of technology like ACLS and annealed alloys, which preserve this sharpness and tolerance.

Using Shredding Machines to Tear Material

Tearing is the process of straining materials so hard that they break. Some items that tear more easily than others are fabrics, soft metals, tires, and plastics. When shredding mixed garbage where maintaining a tiny, constant particle size is not a priority, purpose-built ripping reducers are fantastic.

Material Fracturing in Shredding Equipment

Hard plastics, glass, and some metals are fragile materials that can shatter or break in a shredding machine. However, if the cutters are not tight or sharp, fragments may even be propelled into close people. Eye protection must be used at all times.

Customizing the Design of Shredding Machines

When designing a shredding machine, several factors are taken into account, including the material to be shredded, the volume of material to be shredded, the location of the shredder (on a farm, in an office, outdoors, indoors, etc.), the space allotted for the machine, the frequency at which the shredding machine will be used, and client budget.

Shredding Machine Components

Hooks

The type of material that cutters must grip determines the size and shape of the hooks. Typically, more material can be captured with a larger hook. This hook size will increase the manufacturing rate for various resources. However, it is essential that the hooks only hold as much material as the shredding machine can handle, failing which, there would be repeated redoes and a slowdown in production.

Blades

Tool steel and carburizing steel are commonly used to make shredding blades, although low alloy steels with molybdenum, chromium, and manganese are also used in other applications.

Shaft Dimensions

The primary component of shaft design is determining the appropriate shaft diameter to guarantee adequate rigidity and strength while the shaft is transmitting power under various loading and operating circumstances. The shaft is often made of carbon steel; however, alloy steels like nickel-chromium, nickel, or chrome-vanadium are used when great strength is required.

The following qualities must be present in the material used to make the shaft:

- First, it must be quite strong.

- Next, it must be reasonably machinable.

- Then, it must possess good heat treatment properties.

- Finally, high wearing resistance qualities are required.

Hydraulic or Electric Drive

Depending on the kind of shredding machine, hydraulic or electric systems may be used to rotate the blades. Small paper shredders may use DC motors, while metal shredders may use three-phase AC induction motors. Electric shredding equipment is more energy-efficient than hydraulic shredders, requires less space, and is easier to use and maintain. They are also economical. Electric shredding equipment is suitable and powerful enough to process various materials.

Types of Materials Shredded

Each type of material responds best to a particular shredder type and setting. In addition, the physical characteristics of certain items affect how they respond to the shredding process.

Ductile Material: Ductile material tends to shred into long strips but cannot be easily split. Shearing is the ideal method for shredding ductile material to ensure tiny particle size. Examples include cardboard, paper, cloth, soft metals, rubber, and plastics.

Friable Material: Friable is easily fractured or broken into shards (the reverse of ductile materials). Glass, stone, cast metals, wood, and rigid polymers are some examples. Friable material that has been shredded is more likely to produce little pieces than lengthy strips.

Shredding Machine Variations

The various kinds of shredding equipment include:

Cardboard Shredders

A cardboard shredding machine works similarly to a paper shredding machine for used cardboard boxes.An industrial or commercial recycling device known as a cardboard shredding machine immediately recycles and transforms cardboard waste into packaging material. A piece of cardboard is taken and passed through the front entrance of the shredding machine. The cardboard that has been destroyed falls from the shredder's back. Cardboard scrap is quickly transformed into packaging material with a cardboard shredding machine.

Reusing this cardboard reduces the requirement for packing supplies and waste transportation costs. These cardboard shredding machines can produce chips, flat netting, strips, or cushioned netting. In addition, a cardboard shredding machine creates void-fill materials in various sizes and forms to safeguard items during transportation while also recycling cardboard trash in an eco-friendly manner. Machines for shredding cardboard are easy to use, safe to use, and user-friendly. A switch is used to turn the device on or off.

Document Shredders

A document shredder, or paper shredder, is a piece of electrical equipment used to shred typically sensitive or confidential paper documents into unintelligible fragments. The shredding machine destroys paper documents using a set of rotating cutting blades driven by an electric motor. The type of paper shredding machine determines the size of the output pieces.

Shredders can be divided into three types: strip cut, cross cut, and micro cut. A shredding machine can reduce documents to microscopic paper fragments or long strips as thin as confetti. The authorized security levels of DIN 66399 encompass the output of paper shredding machines.

Choosing the Proper Shredding Machine Manufacturer

To make sure you have the most productive outcome when purchasing shredding machines from a shredding machine manufacturer, it is important to compare at least 4 to 5 companies using our list of shredding machine manufacturers. Each shredding machine company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each shredding machine business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple shredding machine companies with the same quote.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services