Instead of using blades to shred materials, grinders are able to reduce hard, strong material like wood, plastic, clay and shale into powder, dust or shavings by using a high pressure hopper or series of rollers. Certain items are refined to get the desired texture using industrial grinders. Users might acquire finished items that are coarser or finer depending on the type of grinder used. Read More…

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

Tackling the toughest shredding problems since 1980, SSI Shredding Systems designs, manufactures and supports today's most versatile shredders and size reduction solutions.

Our long established Saturn-brand industrial shredders are designed with cost and innovation in mind, and provide the benefit you need no matter what you need to shred!

At Amos Mfg., Inc., we specialize in designing and manufacturing high-quality industrial shredders that are built to handle the toughest materials. With years of experience in the industry, we take pride in offering durable, efficient, and reliable shredding solutions tailored to meet the unique needs of our clients.

More Industrial Grinder Manufacturers

For the purpose of reducing the size of various materials, grinders use a spinning blade or rotating abrasive components. The designed grinder's specs, RPM, and grit will produce a range of particle sizes.

How Industrial Grinders Work

Many mills use a grinding wheel, which can also transfer ground material from the grinding surfaces to a collection area, to break material down into smaller pieces as it rolls against the workpiece. Ball mills, vibratory mills, and rod mills are a few popular types of mills used for industrial grinding. Additionally, wet and dry milling methods are available. These methods are normally selected based on the end-result qualities needed for the material to be ground.

Attrition mills typically use mechanical grinding, which involves physically crushing the material into smaller pieces. In ball mills, the material and several milling balls are fed into a drum; the drum is then rotated on a horizontal axis, forcing the material and the balls to clash and subsequently abrading the material. Similar to rotating mills, vibratory mills crush the material by vibration, usually in addition to rotation.

Types of Industrial Grinders

The different types of industrial grinders include:

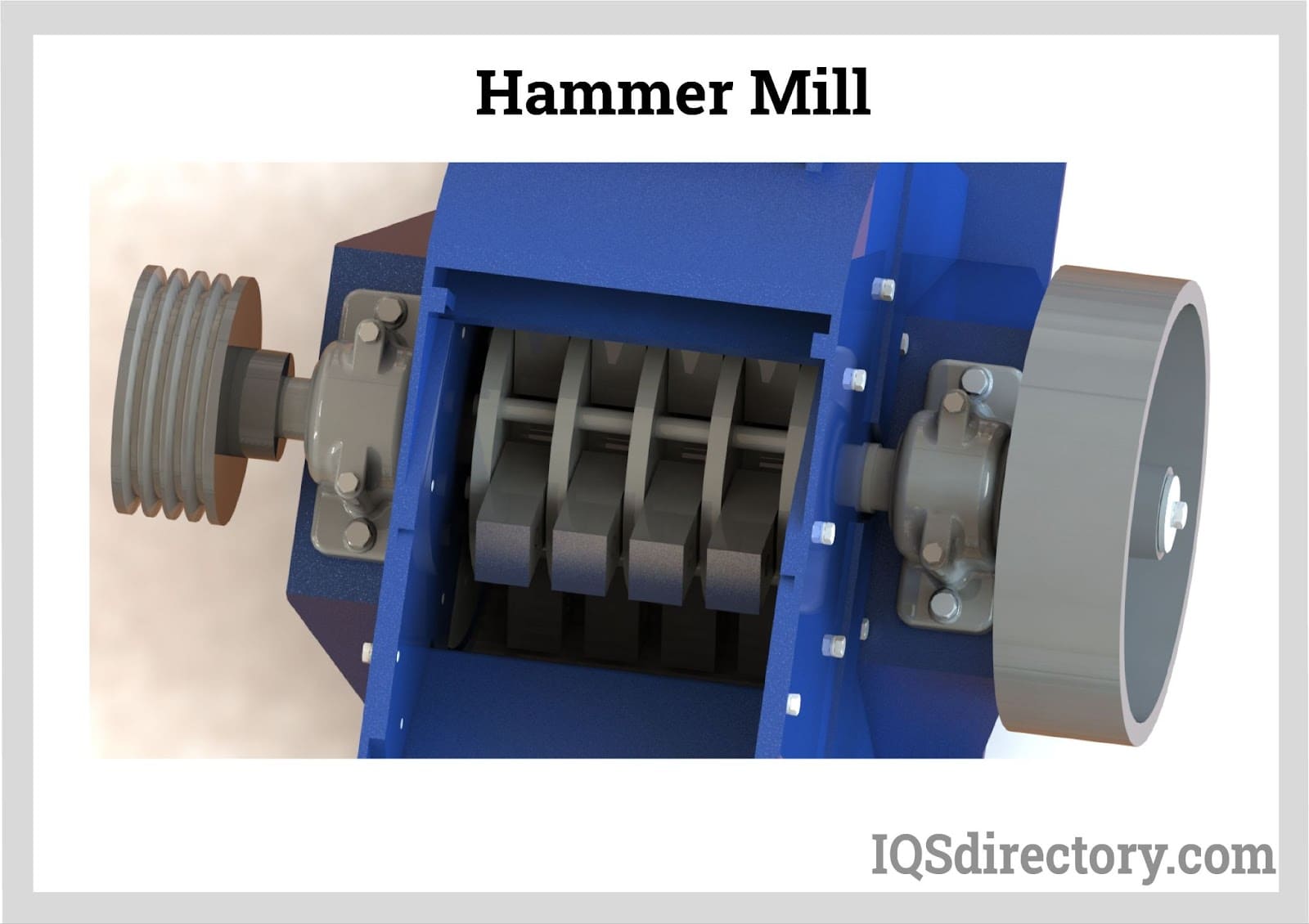

Hammer Mill

A tool called a hammer mill is used to crush materials into extremely small particles. At regular intervals, the grinder's built-in hammers strike the product on the screen. This gadget allows for a completed product that is around 2 mm thick because of the perforation in the screen. Additionally, hammer mills are able to crush materials down to microns. It is possible to mill a variety of components, including minerals, fuels, some metals, various food or medicinal goods, etc., depending on the model and parameters of the industrial mill.

Businesses that handle garbage treatment and recycling also use it. They can, for instance, mill garbage of all kinds including yard waste. Garbage that cannot biodegrade, such as plastics, can still be crushed to these incredibly small pieces.

Roller Mill

The primary grinding is made feasible by this style of industrial mill. The final product is relatively coarse after the process. Two cylinders make up the device, which mills the product. You can either add teeth to the cylinders or keep them completely smooth, depending on the nature and type of grinding you choose. The rate of rotation is also adjustable. This industrial mill has the benefit of emitting relatively little dust while it is running. The roller mill's durability is another benefit. Your roller mill won't be harmed, unlike other industrial mills, even if you introduce objects that can't be milled.

Lump Breaker

It is possible to crush a variety of dense, fatty, or fibrous goods using this industrial crusher. The machine's rotors are fixed with a number of blades. Simply set clumps and water into the crusher to utilize it. The many clumps will be divided by the blades, creating a new usable product.

The Crusher

This industrial grinder can smash a product regardless of its consistency, as the name implies. Typically, the machine is used to crush boulders, stones, and other similar hard products. Gravel, loose stones, and even extremely small particles like sand or dust are produced throughout the operation. Two parallel surfaces make up the crusher. To grind the product, you must place it between the two surfaces. When a certain amount of force is applied, the two surfaces will converge and collide with the product. In order to produce a finer result, the products are broken down in this way.

Ball Mill

Balls are used in ball mills to grind materials. The ball mill is filled with materials like iron ore, cement, and ceramics. The ball mill is then switched on and allowed to begin rotating, either on its vertical or horizontal axis. The balls strike the contained substance as they bounce around in the ball bill while it rotates. These blows have enough force to reduce the material to a finer, less-coarse medium. A ball mill needs to reach critical speed in order to function.

The critical speed of a ball mill is the speed at which the enclosed balls start to rotate along the interior walls. The balls in a ball mill will remain motionless at the bottom where they will have little to no effect on the material if the critical speed is not reached.

Choosing the Proper Industrial Grinder Manufacturer

To make sure you have the most beneficial outcome when purchasing industrial grinders from an industrial grinder manufacturer, it is important to compare at leats 4 to 5 manufacturers using our list of industrial grinder companies. Each industrial grinder manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each industrial gear company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple industrial grinder companies with the same quote.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services